CNC50-3A1S servo bending Pipe Bender Can Bend Steel Pipes And Iron Pipes

CNC50-3A1S pipe Bending

Advantages of equipment use

1. The feeding shaft will perform automatic detection before acting,so that the feeding shaft is avoided from bumping the machine.

2. When the curves are tested,analytical actions can be used,the actions are modified by the careful observation of the interference points ,so that the efficiency is improved.

3. After the data are compiled,the data is protected by a key,so that the data are prevented from any modification.

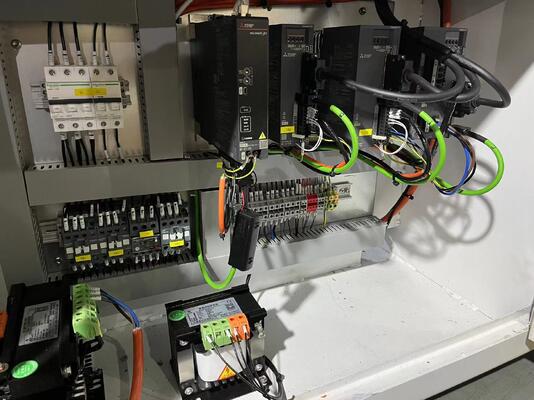

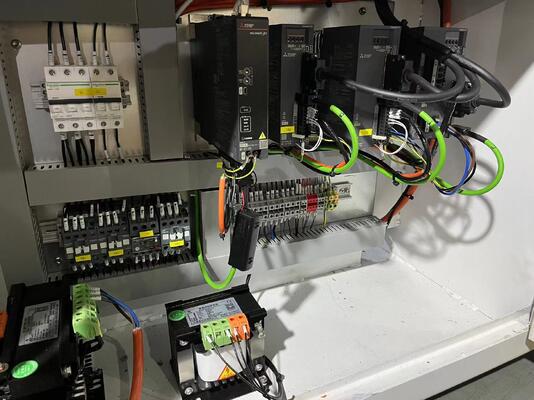

4. The electric control system is equipped with a heat exchanger for automatic heat dissipation;if necessary,a numerical control type refrigerator can be additionally bought,so that the life span of the electric control system is ensured.

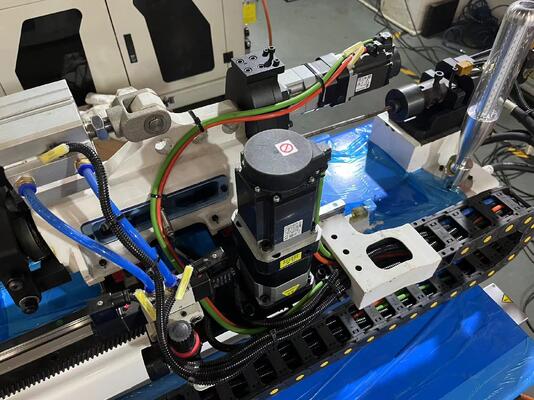

5. An automatic oil charging system is installed to reduce friction of the bending tube.It prolongs the lifetime of the core rod and improves the quality of the bended tube.

6. All processing data are inputted by the touch screen.

7. Based on the change of materials,each curve is set with a compensation value,a speed and a demoulding gap.

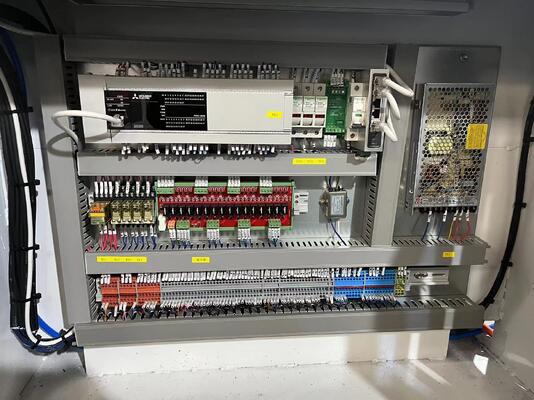

8. The Mitsubishi ultra-large CPU can accommodate 400 groups of files for compiling,if necessary,the additional transmission software is bought and installed in the computer,and the documents and files are stored in the hard disk,so that the number of compiling groups is unlimitedly expanded.

9. Industrial-use computer type:the WINDOWS operating system is internally installed,and used together with the Mitsubishi servo system,besides the Mitsubishi servo driving,the convenient file management owned by the WINDOWS operating system is also provided;and the files can be storted in the hard disk or soft disk,so that the compiling groupnumber is unlimitedly expanded.

10. Chinese/English language are switched to display on the touch screen,and customers can also purchase the machine installed with other languages

Main technical parameters of the equipment CNC50REM

| machine characteristics |

|

main technical parameter |

|

| (1) Electical servo bending |

Max capacity |

round tube/iron tube( S=40kgf/mm ) |

50.8x2.5t |

| (2) Imported servo motor and reducer |

Round tube/non iron metal tube( S=25kgf/mm ) |

50.8x3.5t |

| (3) Independent R & D software system |

Round tube /stainless steel tube( S=60kgf/mm ) |

50.8x1.3t |

| (4) 1-5 layer die optional |

Square tube/Metal Tube( S=40kgf/mm ) |

40x40x1.8t |

| (5) 11 axis full motor type optional |

Round bar( S=40kgf/mm ) |

25 |

| Push-bending type, bending radius7D |

Servo bending axis |

precision |

±0.05 |

| |

max speed |

150°/sec |

| |

Servo material feeding axis |

precision |

0.05mm |

| |

max speed7 |

00mm/sec |

| |

Servo tube rotate axis |

precision |

0.05 |

| |

max speed |

200°/sec |

Machine characteristics:

1. Automatic tube bending machine workstation, Tube bending with several bends in one time.

2. Reduce labor ,saving labor cost.

3. Two automatic feeding machines each feed the tube bender automatically, and a robot loads and palletizes the two tube benders at the same time.

4. The whole process all is controlled by PLC , with touch screen man-machine interface, the efficiency is improved wholely.

5. Automatic Identification of tube welds to make tube Bend Machine avoid Weld seam.

6. Use Industrial Robot for loading and unloading stacking.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!